Teléfono : +86 -13856582579 Correo electrónico : Steven.zhao@ypi-trading.com

Teléfono : +86 -13856582579 Correo electrónico : Steven.zhao@ypi-trading.com

I.Diferencias entre forja y fundición:

1. Definición:

- Forjado: Método de procesamiento en el que los materiales metálicos en estado plástico se martillan o prensan para formar piezas de trabajo de determinadas formas y dimensiones, alterando así sus propiedades físicas.

- Fundición: Método que consiste en convertir metal fundido en líquido, verterlo en un molde y dejarlo enfriar y solidificar para obtener piezas fundidas con la forma deseada. Es adecuado para producir objetos con formas complejas.

2. Proceso de fabricación:

- Forjado: Método que utiliza maquinaria de forjado para aplicar presión a tochos de metal, provocando deformación plástica y obteniendo piezas forjadas con propiedades mecánicas, formas y dimensiones específicas. Es uno de los dos componentes principales del forjado y el estampado.

- Fundición: Método que consiste en verter metal fundido en la cavidad de un molde que coincide con la forma de la pieza y dejar que se enfríe y solidifique para obtener la pieza o la fundición en bruto.

II. Aplicaciones de la forja y la fundición:

- La forja se utiliza generalmente para procesar piezas con formas y dimensiones específicas.

- La fundición es un método económico para formar piezas fundidas en bruto y se utiliza normalmente para piezas con formas complejas.

III. Ventajas y desventajas de la forja y la fundición:

Ventajas de la forja:

La forja elimina defectos como la porosidad que se forma durante la fundición, refina la microestructura y preserva la continuidad del grano metálico. Por consiguiente, las piezas forjadas suelen presentar propiedades mecánicas superiores a las de las piezas fundidas del mismo material. Los componentes críticos de la maquinaria que soportan cargas elevadas y condiciones de trabajo exigentes a menudo son piezas forjadas, salvo las formas más sencillas que pueden fabricarse a partir de chapas laminadas, perfiles o piezas soldadas.

Ventajas de la fundición:

1. Capaz de producir piezas con formas complejas, especialmente aquellas con cavidades internas intrincadas.

2. Amplia aplicabilidad, ya que se pueden fundir metales industriales de uso común, desde unos pocos gramos hasta cientos de toneladas.

3. Las materias primas son abundantes y económicas, como chatarra de acero, piezas desechadas y virutas.

4. La forma y las dimensiones de las piezas fundidas son muy similares a las de la pieza final, lo que reduce la necesidad de mecanizado y permite un procesamiento casi con forma final.

5. Ampliamente utilizado; las piezas fundidas representan entre el 40% y el 70% de la maquinaria agrícola y entre el 70% y el 80% de las máquinas herramienta en peso.

Desventajas de la forja:

- La producción de forja es propensa a sufrir lesiones accidentales.

Desventajas del casting:

1. Las propiedades mecánicas son inferiores a las de las piezas forjadas, con problemas como una microestructura gruesa y numerosos defectos.

2. En la fundición en arena, la producción a pequeña escala o de piezas únicas implica una alta intensidad de mano de obra.

3. La calidad de la fundición es inestable debido a múltiples procesos y factores de influencia complejos, lo que conduce a diversos defectos.

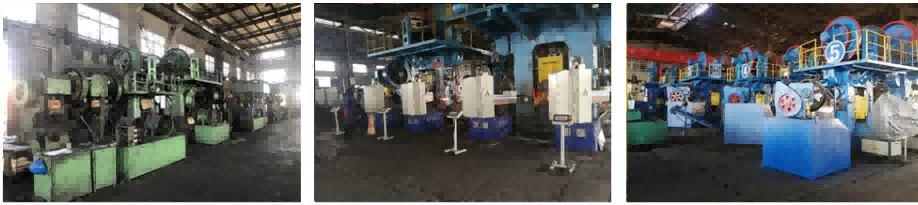

yuanpeng Mantenemos relaciones de colaboración sólidas y duraderas con la fábrica desde hace aproximadamente 20 años. La fábrica cuenta con una gran capacidad de producción mecánica y automatizada que garantiza la calidad y el rendimiento estables de las piezas forjadas/fundidas, así como una buena consistencia.

ETIQUETAS :

Dejar un mensaje

Scan to Wechat/Whatsapp: